- Home

- >

- News

- >

- Industry News

- >

- Advantages of cemented carbide nozzles

Advantages of cemented carbide nozzles

Advantages of cemented carbide nozzles

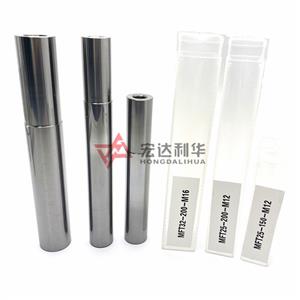

Tungsten steel nozzle [hard alloy nozzle] is made by hot pressing of hot straight holes and small holes. Due to its hardness, low density and excellent resistance to wear and corrosion, carbide nozzles have been widely used in sand blasting and shot peening equipment to ensure long-term use in the best air and abrasive materials.

Carbide nozzles are machined from precision machinery and hard alloy materials (superhard alloys). The bending resistance reaches 2300N/mm and the hardness reaches 90 degrees HRA. When machining cemented carbide nozzles, we perform precision grinding and surface treatment to achieve a hole roughness of Ra0.1 and a roughness of Ra 0.025 at both ends. There is a scientific radius of curvature design at the two entrances. This design ensures smooth passage of the thread. Due to the overall material processing, there is no elevation angle on the borehole, and the tendency to bend and block is improved relative to the ruby nozzle.

Tungsten steel nozzle use

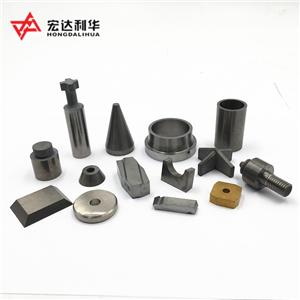

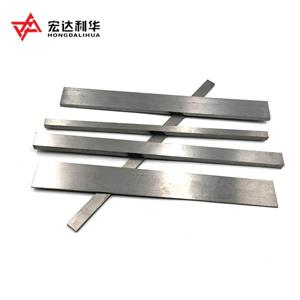

Carbide nozzles are mainly used for cooling drill teeth, flushing mud and cleaning downhole cuttings when working with tools such as PDC bits and roller cones for oil and gas drilling. Cemented carbide has a series of excellent properties such as high hardness, wear resistance, strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which remains basically unchanged even at a temperature of 500 ° C. It still has a high hardness at 1000 °C. Carbide is widely used as a tool material, such as turning tools, milling cutters, planers, drills, boring tools, etc., for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and ordinary steel, can also be used for cutting Hard-to-machine materials such as heat-resistant steel, stainless steel, high manganese steel, and tool steel.carbide nozzles offer the advantages of economy and long life when unavoidably rough handling and medium for cutting abrasives (glass beads, steel shots, minerals or cinder). Conventionally, cemented carbide is the material of choice for cemented carbide nozzles.

Tungsten steel nozzle use:

It is widely used in surface treatment, sandblasting, painting, electronics, chemical processes and other industries.

Advantages of tungsten steel nozzles:

Corrosion resistance, long service life, excellent performance, high cost performance, and low wear resistance.