- Home

- >

- Products

- >

- Tungsten Carbide Rods

- >

- YG10X Solid Tungsten Rods With Wear Resistance

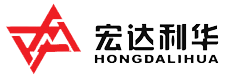

YG10X Solid Tungsten Rods With Wear Resistance

Brand :Lihua

Product origin :Zhuzhou, China

Delivery time :7-15 Working Days

Supply capacity :15 Ton per Month

Cheap price YG10X Solid Tungsten alloy carbide composite Rods With Wear Resistance Suppliers Quotes For production various types electrical machine & electronic progressive dies and punches.

Cheap Solid Tungsten Rods, tungsten carbide composite rods Suppliers, tungsten rod Quotes, tungsten alloy rod price

YG10X Solid Tungsten Rods With Wear Resistance

Applications

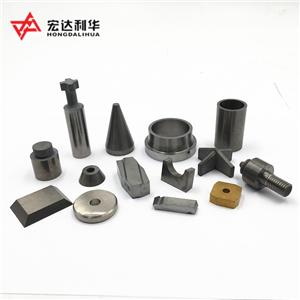

It is suitable for the production of various types electrical machine & electronic progressive dies and punches. And widely used in ceramics, printing machine, plastic, rubber, leather industry and cutting machines, CNC machine, CNC, PCB micro drill bits, etc.

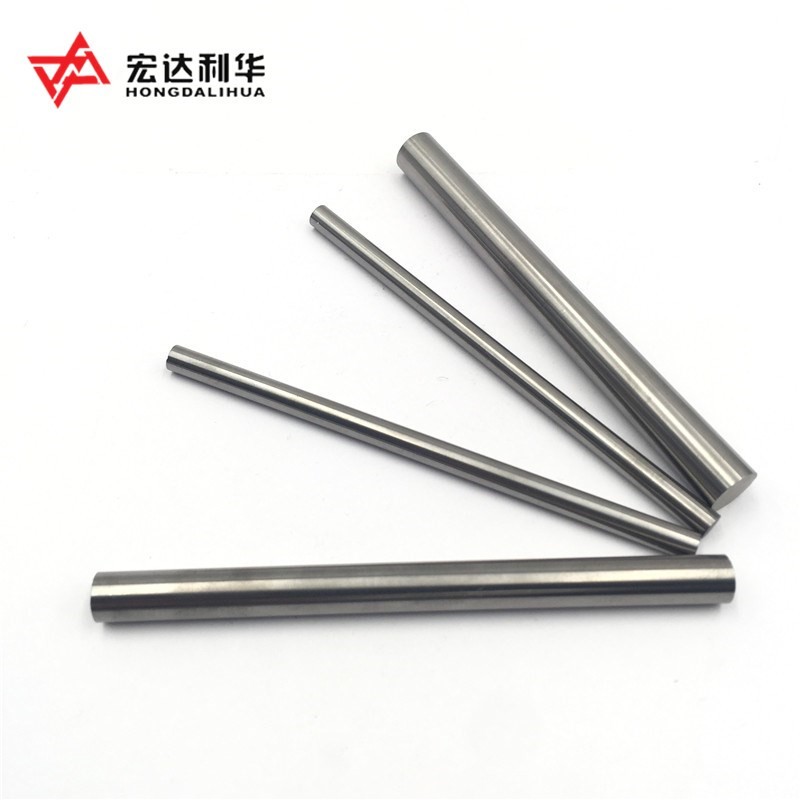

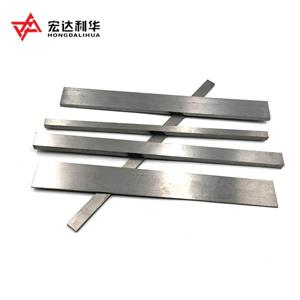

Details of Tungsten Solid Carbide Rods

| Product name | Solid carbide Rod / Bar / Stick |

| OD tolerance | 0.5um |

| Surface fineness | Ra0.025a |

| Sizes | Diamter:Φ0.5-Φ0.35mm,Length:100-330mm(diameter is Φ1.0-Φ6.0mm,lenght can up 700mm) |

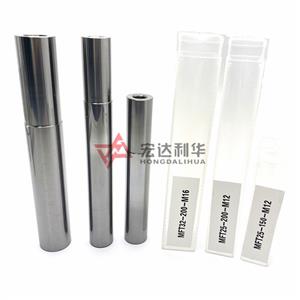

| Type | Round(solid,hollow) |

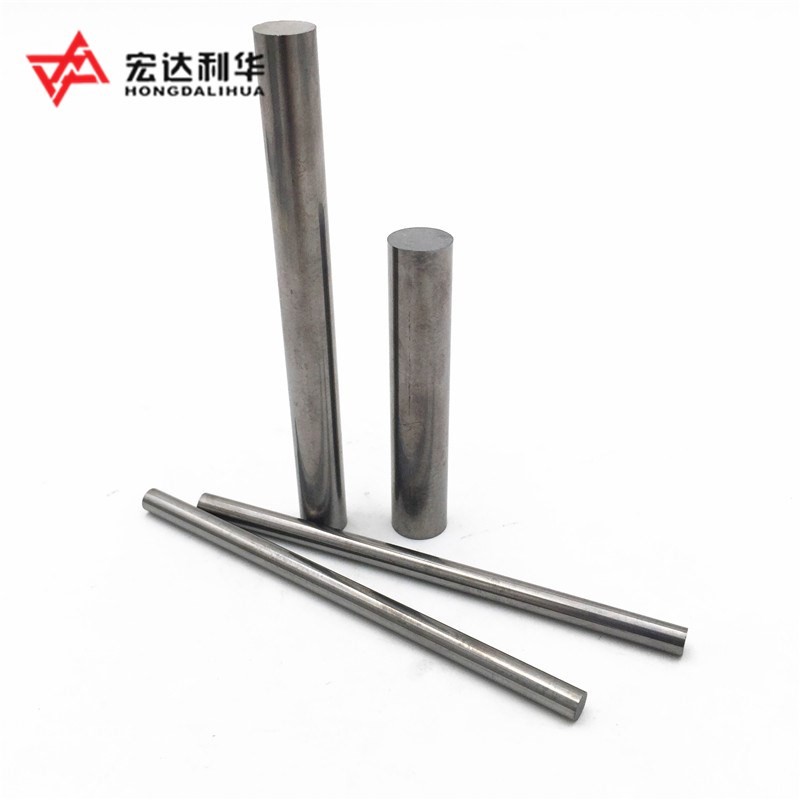

Grade | YL10.2, K20,K30 ,YL50,YU06A,YU06R,YF06,YH6F,YG11 etc. |

| Material | 100% Tungsten Raw Materials |

Physical performance | High Precision , hardness,strength, wear resistance . |

Application | For production various types electrical machine & electronic progressive dies and punches.And ceramics, printing machine, plastic, rubber, leather industry and cutting machines. |

Non-standard or Tolerance | Can be customized |

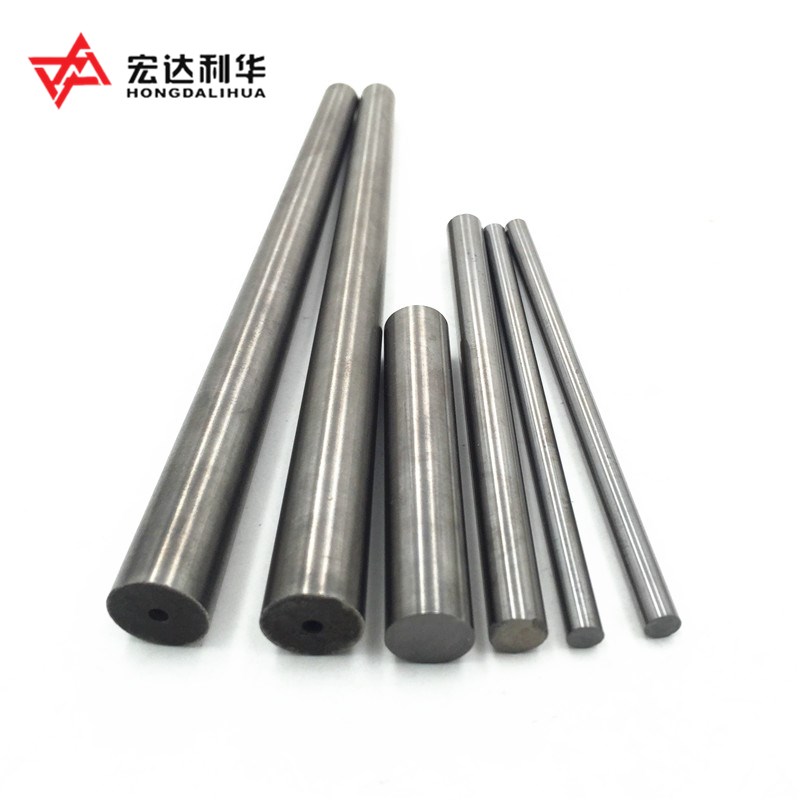

1)Solid tungsten carbide rod/bar/stick

Diameter(D) | Tolerance | Standard length |

Φ0.5~5.5 | +0.30~+0.45 | 330~500 (+5.0/0) |

Φ6.0~50.0 | +0.20~+0.60 | 330~500(+5.0/0) |

2)Hollow tungsten carbide rod/bar/stick

Outer Diameter | Tolerance of Outer Diameter | Diameter of Hole | Tolerance of Hole | Standard Length |

Φ2.5~8.0 | +0.2~+0.5 | 0.3~1.5 | +/-0.15 | 330~500 (+5.0/0) |

Φ10.0~50.0 | +0.3~+0.8 | 2.0~5.0 | +/-0.30 | 330~500 (+5.0/0) |

Dimensions of Tungsten Carbide Rods

Type | Tolerance of diameter(mm) | Tolerance of length(mm) | Type | Tolerance of diameter(mm) | Tolerance of length(mm) |

Φ3.0×320 | ±0.5/0.6 | 0/+5.0 | φ8.0×45 | ±0.5/0.6 | 0/+5.00 |

Φ3.5×320 | ±0.5/0.6 | 0/+5.0 | φ8.0×50 | ±0.5/0.6 | 0/+5.0 |

Φ4.0×320 | ±0.5/0.6 | 0/+5.0 | Φ8.0×320 | ±0.5/0.6 | 0/+5.0 |

φ4.5×320 | ±0.5/0.6 | 0/+5.0 | φ8.6×320 | ±0.5/0.6 | 0/+5.0 |

φ4.0×150 | ±0.5/0.6 | 0/+5.0 | φ8.0×150 | ±0.5/0.6 | 0/+5.0 |

φ5.0×36 | ±0.5/0.6 | 0/+5.0 | Φ9.0×320 | ±0.5/0.6 | 0/+5.0 |

φ5.0×80 | ±0.5/0.6 | 0/+5.0 | φ10.6×320 | ±0.5/0.6 | 0/+5.0 |

φ5.0×40 | ±0.5/0.6 | 0/+5.0 | φ10.0×65 | ±0.5/0.6 | 0/+5.0 |

| φ5.0×100 | ±0.5/0.6 | 0/+5.0 | φ10.0×60 | ±0.5/0.6 | 0/+5.0 |

Φ5.0×320 | ±0.5/0.6 | 0/+5.0 | φ10.0×55 | ±0.5/0.6 | 0/+5.0 |

Φ5.5×320 | ±0.5/0.6 | 0/+5.0 | φ12.0×78 | ±0.5/0.6 | 0/+5.0 |

Φ6.0×100 | ±0.5/0.6 | 0/+5.0 | φ12.0×150 | ±0.5/0.6 | 0/+5.0 |

| Φ6.0×320 | ±0.5/0.6 | 0/+5.0 | φ12.0×130 | ±0.5/0.6 | 0/+5.0 |

Φ6.6×320 | ±0.5/0.6 | 0/+5.0 | φ12.6×320 | ±0.5/0.6 | 0/+5.0 |

Φ7.0×320 | ±0.5/0.6 | 0/+5.0 | φ15.6×320 | ±0.5/0.6 | 0/+5.0 |

φ7.0×60 | ±0.5/0.6 | 0/+5.0 | φ16.0×100 | ±0.5/0.6 | 0/+5.0 |

φ7.6×320 | ±0.5/0.6 | 0/+5.0 | φ16.6×320 | ±0.5/0.6 | 0/+5.0 |

φ8.0×80 | ±0.5/0.6 | 0/+5.0 | φ18.6×320 | ±0.5/0.6 | 0/+5.0 |

φ8.0×40 | ±0.5/0.6 | 0/+5.0 | φ25.0×320 | ±0.5/0.6 | 0/+5.0 |

Tungsten Carbide Grade Information

Grade | Density g/cm3 | Hardness HRA(hv) | T.R.S (MPa) | Performances &applications recommended |

YG6 | 14.9 | 89.5 | 2150 | Good Wear resistance, used for hard wood, processing original wood, aluminum section bar, brass rod and cast iron. |

YG8 | 14.6 | 89 | 2320 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

YG11 | 14.4 | 87.5 | 2260 | Medium grain, for wear parts and mining tools |

YG15 | 14.1 | 86.5 | 2400 | Medium grain, for mining tools, cold heading and punching dies |

YS2T | 14.45 | 92.5 | 2800 | Fine carbide,high wear resistance, high bending strength, high resistance to bonding, high thermal strength. Machining of refractory alloys, stainless steel and high manganese steel etc. Mainly used for disc cutter and other tools |

YL10.2 | 14.5 | 92.5 | 3400 | Wear resistance and strength comparatively higher,suitable for processing cast iron, non-ferrous metal and non-metalloid materials. |

YNi8 | 14.6 | 88.5 | 1710 | This grade with 8% nickel binder, it has good wear resistance& corrosion resistance performance ,especially used for high pressure environmental , also good for cutting the titanium alloy. |

YG10X Solid Tungsten Rods With Wear Resistance

Tungsten Carbide Rods For Milling Cutter Machine With Good Price

330mm Length Tungsten Carbide Rod For Carbide Endmil

-

Download

- sd1584514742_2.MP4