- Home

- >

- News

- >

- Industry News

- >

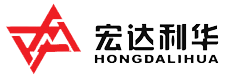

- Tungsten carbide plate features

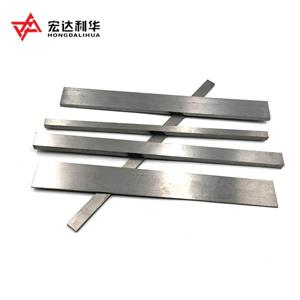

Tungsten carbide plate features

Tungsten carbide plate features

Tungsten alloys are alloys of other elements added on the basis of tungsten. Among metals, tungsten has the highest melting point, high temperature strength and creep resistance, and good thermal conductivity, electrical conductivity and electron emission performance. It is widely used in addition to tungsten carbide and its alloys. In the electronics and electric light source industries, it is also used in aerospace, casting, weapons and other sectors to make rocket nozzles, die-casting molds, armor-piercing cores, contacts, heating elements and heat shields.

Molybdenum tungsten alloy

An alloy containing both molybdenum and tungsten, including a molybdenum-based molybdenum-tungsten alloy and a tungsten-based tungsten-molybdenum alloy series. The alloy can be formed in any ratio and is a complete solid solution alloy at all temperatures.

Tungsten tungsten alloy

A niobium alloy formed by adding a certain amount of tungsten and other elements to the niobium. Tungsten and niobium form an infinite solid solution. Tungsten is an effective strengthening element of niobium, but as the amount of tungsten added increases, the plastic-brittle transition temperature of the alloy will increase and the grains will grow significantly. Therefore, in order to obtain a high-strength tantalum-tungsten alloy, it is necessary to appropriately control the amount of tungsten added, and at the same time, an appropriate amount of elements such as zirconium and hafnium which refine grains and lower the plastic-brittle transition temperature must be added. In 1961, the United States successfully developed the Nb-10W-2.5Zr alloy for the space shuttle skin, and later developed into the Nb-10W-1Zr-0.1C alloy. In the early 1970s, China also developed NbWl0Zr2.5 and NbWl0Zr1C0.1 alloys.

Cemented carbide

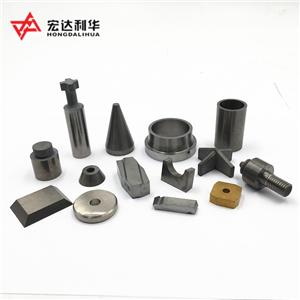

Cemented carbide is the most common and dominant form of tungsten alloy. Unlike the previous tungsten alloys, which are tungsten and carbon, cobalt, it is also often referred to as tungsten-cobalt alloy. At present, the most widely used tools in the industrial field are basically cemented carbide tools, so the tungsten alloy such as cemented carbide is also called "industrial teeth."

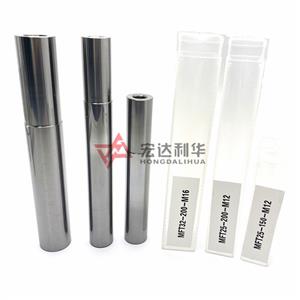

Tungsten-Carbide-Plates,Tungsten-Carbide-Rods,Tungsten-Carbide-Rods,Carbide Rings