- Home

- >

- Factory show

- >

- Tungsten Carbide Plates

- >

- Factory Supply ! Tungsten Carbide Plates For Punching Crushing Stone And Mould Making

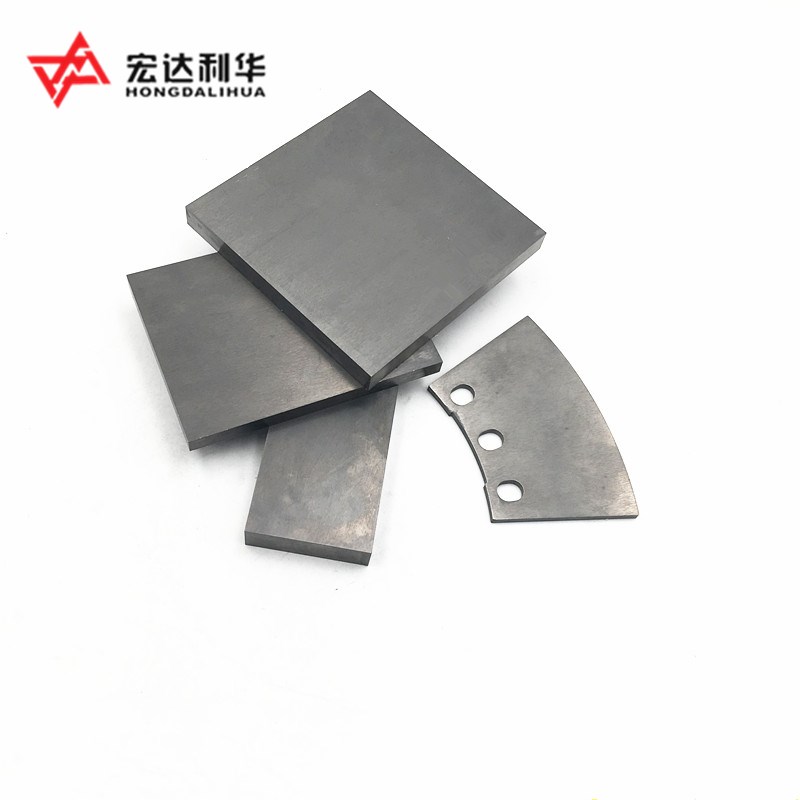

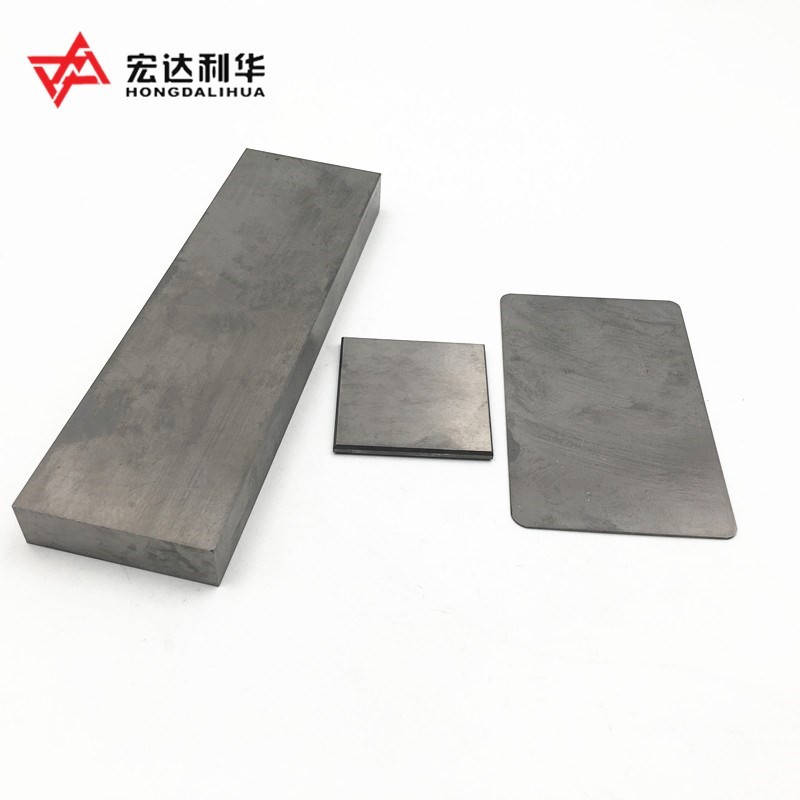

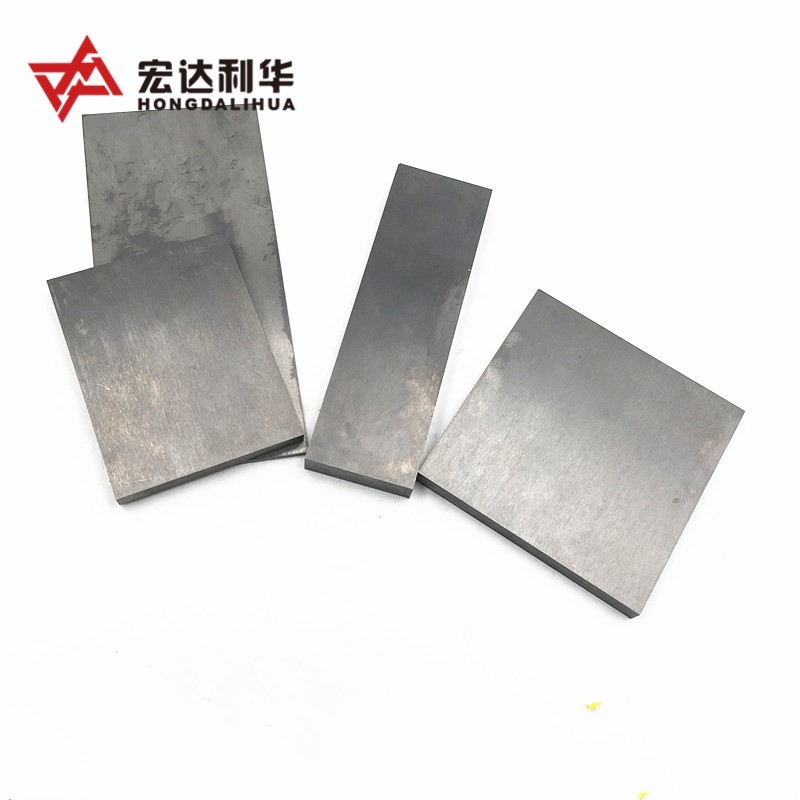

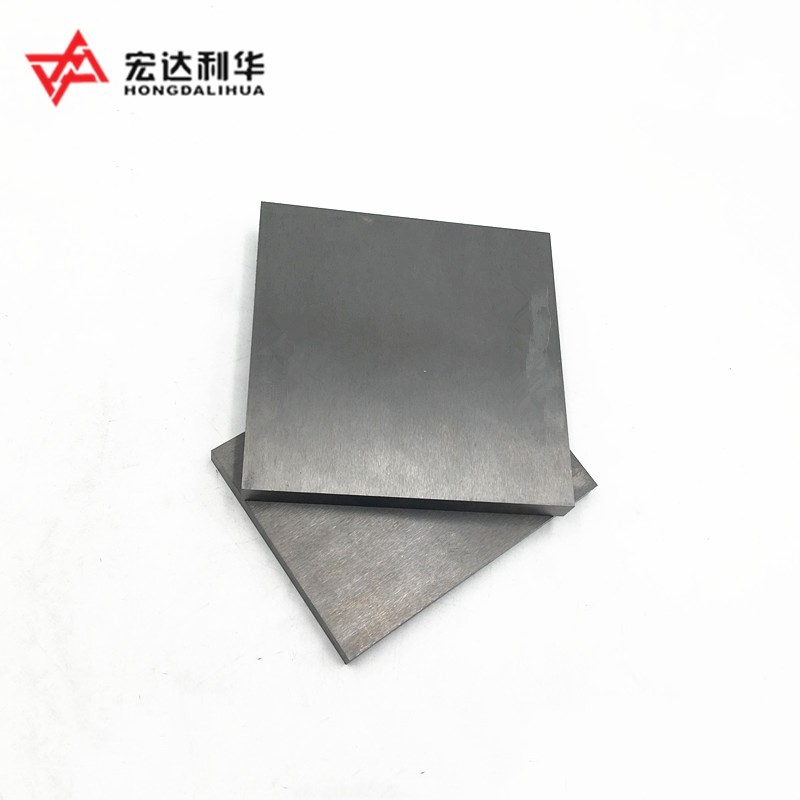

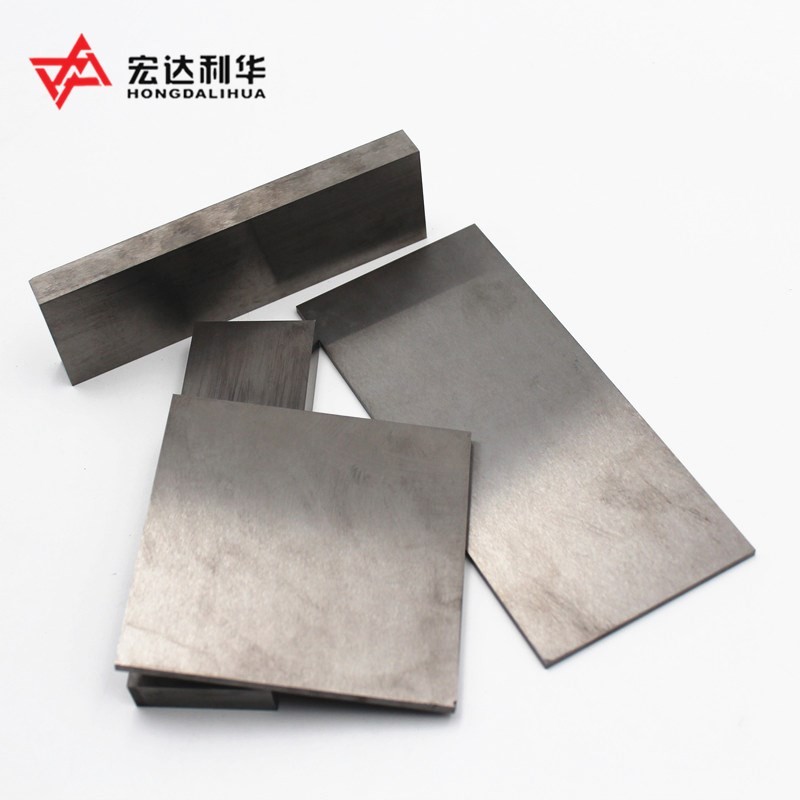

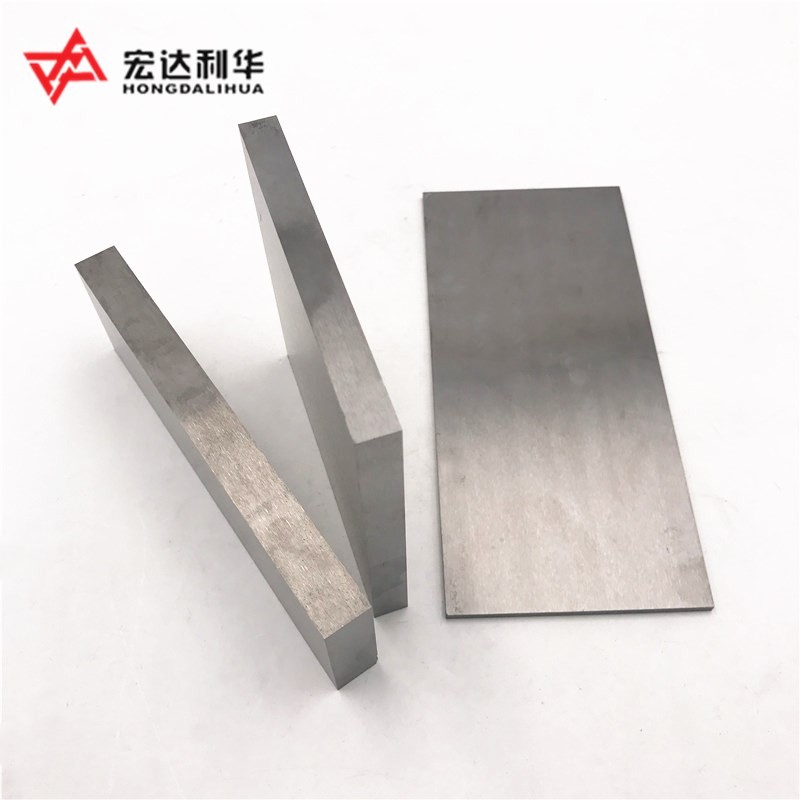

Factory Supply ! Tungsten Carbide Plates For Punching Crushing Stone And Mould Making

Brand :Lihua

Product origin :Zhuzhou, China

Delivery time :7-15 Working Days

Supply capacity :15 Ton per Month

Factory Supply ! Tungsten Carbide Plates for Punching Crushing Stone and Mould Making

Applications

Carbide plate is a highly efficient and green material, which features qualities of stainless steel: Corrosion resistance, oxidation resistance, wear resistance, bonding proof and acid-base resistance; And ensures its good strength, toughness, bending and stretching, impact resistance.

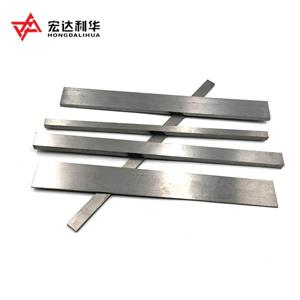

Tungsten carbide strip is used for woodworking cast iron cutting tool. It can be used in many field such as woodworking, machining of refractory alloys, stainless steel, high manganese steel, for processing cast iron, non-ferrous metal and aluminum section bar, etc.

Advantages

1. Superior heat stability.

2. Anti-deformation in high temperature.

3. Fine thermal shock resistance.

4. High thermal conductivity.

5. Excellent Oxidation control ability.

6. Strong anti-corrosion in high temperature.

7. Good corrosion resistance from Chemical.

8. High-wearing feature.

9. Long usage lifetime.

Grade Recommended

The grades which used more frequently are YG8, YG15, YG20, YG10.2, YG2T, YG10X etc.

Other grades can be offered according to customers’ requirements. Afterwards the board can be broken out from the panel.

Grade | Density (g/cm3) | T.R.S (MPa) | Hardness (HRA) | Performance & Application recommended |

YL10.2 | 14.50 | 3400 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,espercially for cut-off tool and sick prick. |

YG11C | 14.40 | 2260 | 87.5 | Qualified for molding the drills for heavy-duty rock drill:detachable bits used for deep hole drilling,rock drill torlley etc. |

YG6X | 14.90 | 1560 | 91.0 | Qualified for machiningof chilled cast iron,alloy cast iron,refractory steel ana alloy steel.Also qualified for the machining of common cast iron. |

YS2T | 14.45 | 2800 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,espercially for cut-off tool and sick prick. |

YG15 | 14.10 | 2400 | 86.5 | Used for punch dies,stamping dies and wear resistance parts. |

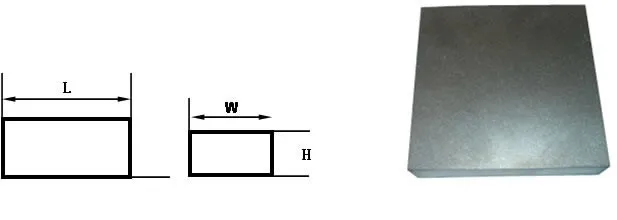

unit: mm

TYPE | TOLERANCE | |||

GROUND | UNGROUND | |||

H | W | L | ||

100×100(1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

105×105(1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

150×150(5.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

200×200(5.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

200×100(1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

200×160(1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

120×120(1.0~70) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

150×120(1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

170×80×(1.0~20) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

150×100(1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

100×90(1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

100×80(1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

100×50(1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |

100×60(1.0~40) | +0.5 | ±2.2 | ±2.2 | ±0.01 |