- Home

- >

- Products

- >

- Tungsten Carbide TC Spray Nozzles

- >

- High Pressure Tungsten Carbide flat TC Tips For Painting ,glazing ,cleaning ,cleaning

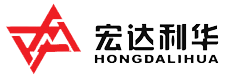

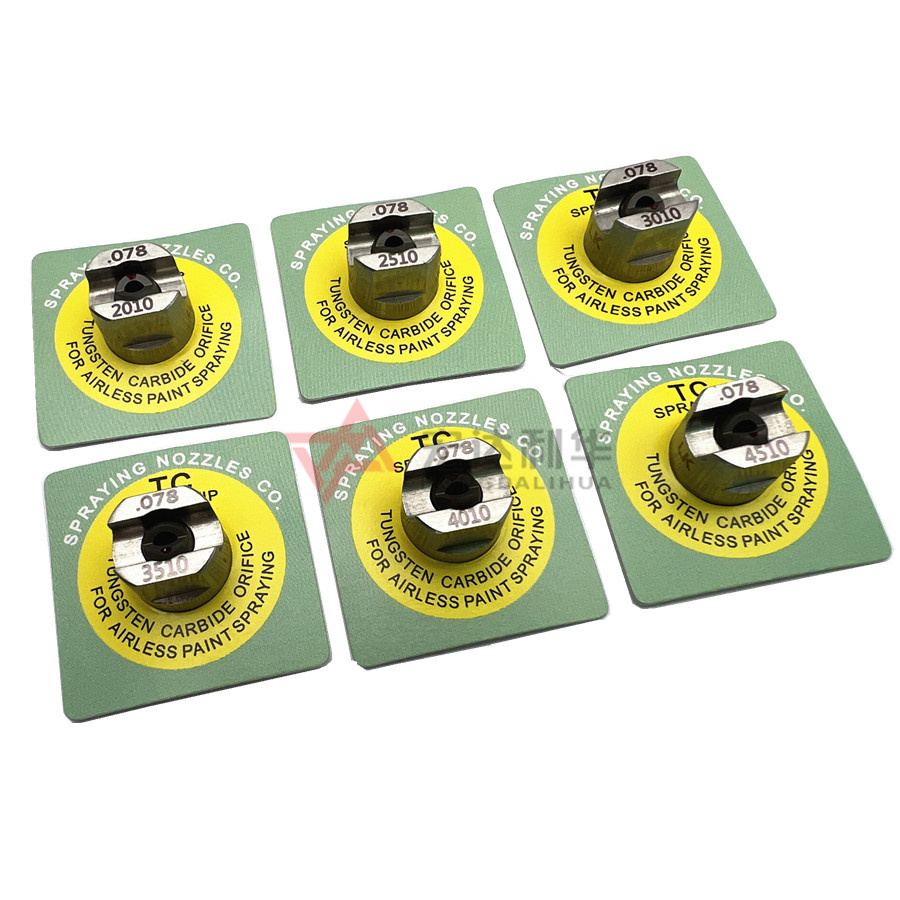

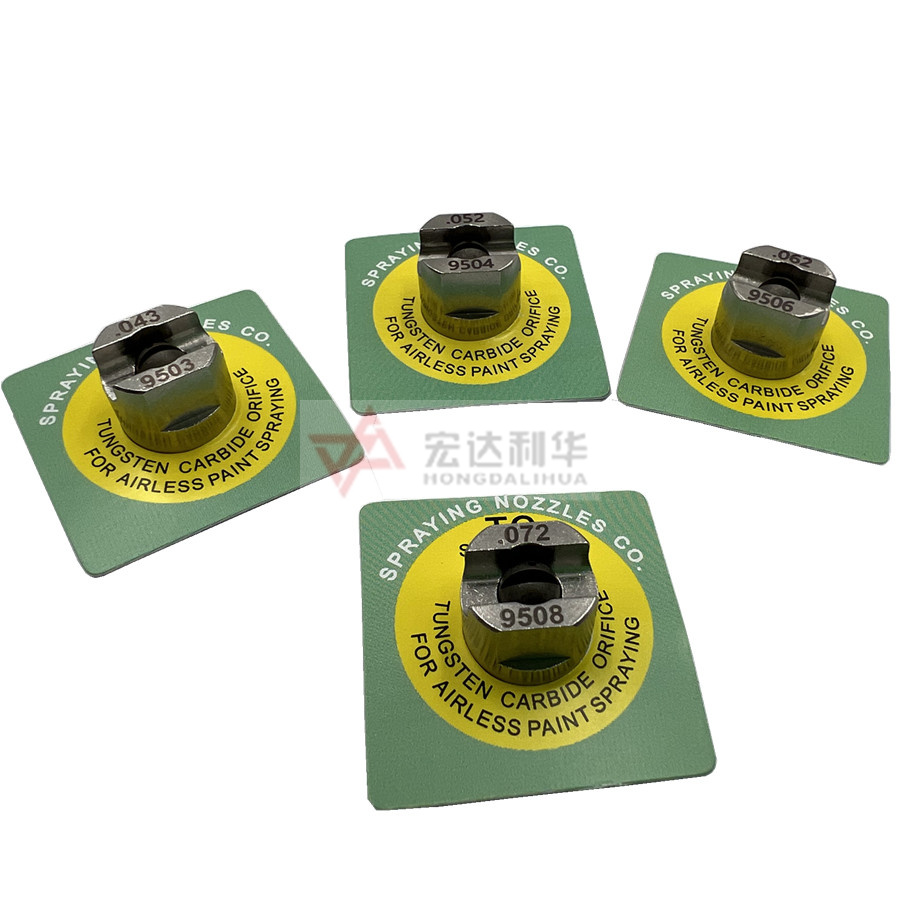

High Pressure Tungsten Carbide flat TC Tips For Painting ,glazing ,cleaning ,cleaning

Brand :LIHUA

Product origin :Zhuzhou ,China

Delivery time :7-15 working days

Supply capacity :15 Ton per Month

Sales china High Pressure Tungsten Carbide TC Tips saw sawzall blades Factory 2. Erosion-resistance tungsten carbide orifice insert provides. 3. Excellent Corrosion Resistance.

Sales High Pressure Tungsten Carbide TC Tips, china carbide tipped sawzall blades, carbide tipped saw Factory

Advantage

1. Ideal for paint spraying and the application of sealants and protective coatings in automotive manufacturing.

2. Erosion-resistance tungsten carbide orifice insert provides.

3. Excellent Corrosion Resistance.

4. High-impact flat spray pattern with tapered edges, provides even coverage when sprays overlap.

5. Tip orifice inserts is recessed in a solid stainless steel tip body to protect against damage.

Grade Information

| Grade | Density(g/cm3) | T.R.S MPa | Hardness(HRA) | Performance & Application recommended |

| YL10.2 | 14.50 | 3400 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,especially for cut-off tool and sick prick. |

| YG3 | 15.20-15.40 | 1400 | 91.5 | Medium grain,for finishing machining of cast iron and non-ferrous Metals |

| YG6X | 14.90 | 1560 | 91.0 | Qualified for machining of chilled cast iron,alloy cast iron,refractory steel analloy steel.Also qualified for the machining of common cast iron. |

| YS2T | 14.45 | 2800 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,especially for cut-off tool and sick prick. |

| YG3X | 15.20-15.40 | 1300 | 92 | Fine Grain,for finishing machining of cast iron and non-ferrous metals |

High-Pressure TC Tips Performance Parameter

| Spray Angle at 3 bar | Spray Tip No. |

Equiv.Orifice Dia(mm) | Capacity*(liters Per Minute) | Appro.**Spray Pttern Width(cm)at 30cm Distance | |||

| 50Bar | 100Bar | 150Bar | 200Bar | ||||

| 110° | 110017-TC | 28 | 27 | 39 | 47 | 55 | 39 |

| 1100025-TC | 33 | 40 | 57 | 70 | 81 | 42 | |

| 1100033-TC | 38 | 53 | 75 | 92 | 1.1 | 43 | |

| 1100039-TC | 41 | 63 | 89 | 1.1 | 1.3 | 46 | |

| 100050-TC | 46 | 81 | 1.1 | 1.4 | 1.6 | 48 | |

| 1100067-TC | 53 | 1.1 | 1.5 | 1.9 | 2.2 | 53 | |

| 1100080-TC | 58 | 1.3 | 1.8 | 2.2 | 2.6 | 56 | |

| 11001-TC | 66 | 1.6 | 2.3 | 2.8 | 3.2 | 58 | |

| 110015-TC | 79 | 2.4 | 3.4 | 4.2 | 4.8 | 63 | |

| 11002-TC | 91 | 3.2 | 4.6 | 5.6 | 6.4 | 66 | |

| 11003-TC | 1.1 | 4.8 | 6.8 | 8.4 | 9.7 | 68 | |

| 11004-TC | 1.3 | 6.4 | 9.1 | 11.2 | 12.9 | 71 | |

| 11005-TC | 1.4 | 8.1 | 11.4 | 14.0 | 16.1 | 71 | |

| 110053-TC | 1.5 | 8.5 | 12.1 | 14.8 | 17.1 | 71 | |

| 11006-TC | 1.6 | 9.7 | 13.7 | 16.7 | 19.3 | 71 | |

| 11007-TC | 1.7 | 11.3 | 16.0 | 19.5 | 23 | 71 | |

| 11008-TC | 1.8 | 12.9 | 18.2 | 22 | 26 | 71 | |

| 11009-TC | 1.9 | 14.5 | 21 | 25 | 29 | 71 | |

| 11010-TC | 2.0 | 16.1 | 23 | 28 | 32 | 71 | |

| 11011-TC | 2.2 | 17.7 | 25 | 31 | 35 | 71 | |

| 11012-TC | 2.3 | 19.3 | 27 | 33 | 39 | 71 | |

| 65° | 650055-TC | 48 | 88 | 1.3 | 1.5 | 1.8 | 33 |

| 650067-TC | 53 | 1.1 | 1.5 | 1.9 | 2.2 | 38 | |

| 650080-TC | 58 | 1.3 | 1.8 | 2.2 | 2.6 | 38 | |

| 95° | 9503-TC | 1.1 | 4.8 | 6.8 | 8.4 | 9.7 | 56 |

Know more it pls contact us

Sales Manager : Coco Su

Mobile/WhatsApp:+86 13973352165

Skype : Carbide tools

QQ: 1638174610/1007161690

WeChat: 13973352165/cocosd79

Email: coco@lihuacarbide.com / hongda@lihuacarbide.com

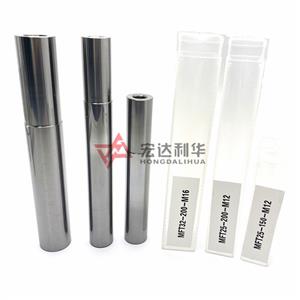

Tungsten Cemented Carbide Bushings Tube For Oil And Well Drilling

High Precision Down Hole Parts Tungsten Carbide Bushing