- Home

- >

- Products

- >

- Tungsten Carbide Saw Blades

- >

- New Developed Tungsten Carbide V Cut Saw Blade For PCB

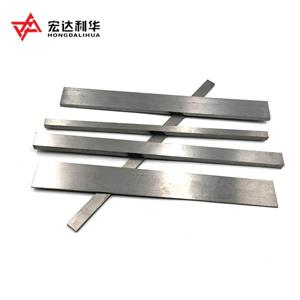

New Developed Tungsten Carbide V Cut Saw Blade For PCB

Brand :LIHUA

Product origin :Zhuzhou ,China

Delivery time :7-15 working days

Supply capacity :15 Ton per Month

Applications:

It is suitable for scoring the surface of PCB, yielding a stabilized burr-free V-like groove(30°45°60°90°etc) and for cutting wood, metal, aluminum & plastic composites, MDF,non-ferrous metals, PVC, PCB, graphite, brass rod, cast iron, granite, marble and grass etc

Advantage: A high hardness, high corrosion resistance, high wear resistance, long service life and improve production efficiency. Precision machining, high surface finish, high processing V groove surface finish, no burr, greatly improved the quantity of products

Dimensions of Tungsten Carbide Saw Blade

Inch | Diameter | Central hole | Segment thickness | Teeth |

4" | 105 | 20 | 1.8 | 30/40 |

7" | 180 | 25.4 | 2.2 | 40/60/80 |

8" | 200 | 25.4 | 2.6 | 40/60/80 |

9" | 230 | 25.4 | 2.8 | 40/60/80 |

10" | 250 | 30 | 3 | 40/60/80/100/120 |

12" | 300 | 30 | 3.2 | 40/60/80/100/120 |

14" | 350 | 30 | 3.4 | 60/80/100/120 |

16" | 400 | 30 | 3.6 | 60/80/100/120 |

Grade Information

Grade | Density g/cm3 | T.R.S MPa | Hardness HRA | Performance & Application recommended |

YL10.2 | 14.50 | 3400 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,espercially for cut-off tool and sick prick. |

YG11C | 14.40 | 2260 | 87.5 | Qualified for molding the drills for heavy-duty rock drill:detachable bits used for deep hole drilling,rock drill torlley etc. |

YG6X | 14.90 | 1560 | 91.0 | Qualified for machiningof chilled cast iron,alloy cast iron,refractory steel ana alloy steel.Also qualified for the machining of common cast iron. |

YS2T | 14.45 | 2800 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,espercially for cut-off tool and sick prick. |

YG15 | 14.10 | 2400 | 86.5 | Used for punch dies,stamping dies and wear resistance parts. |