- Home

- >

- Products

- >

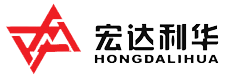

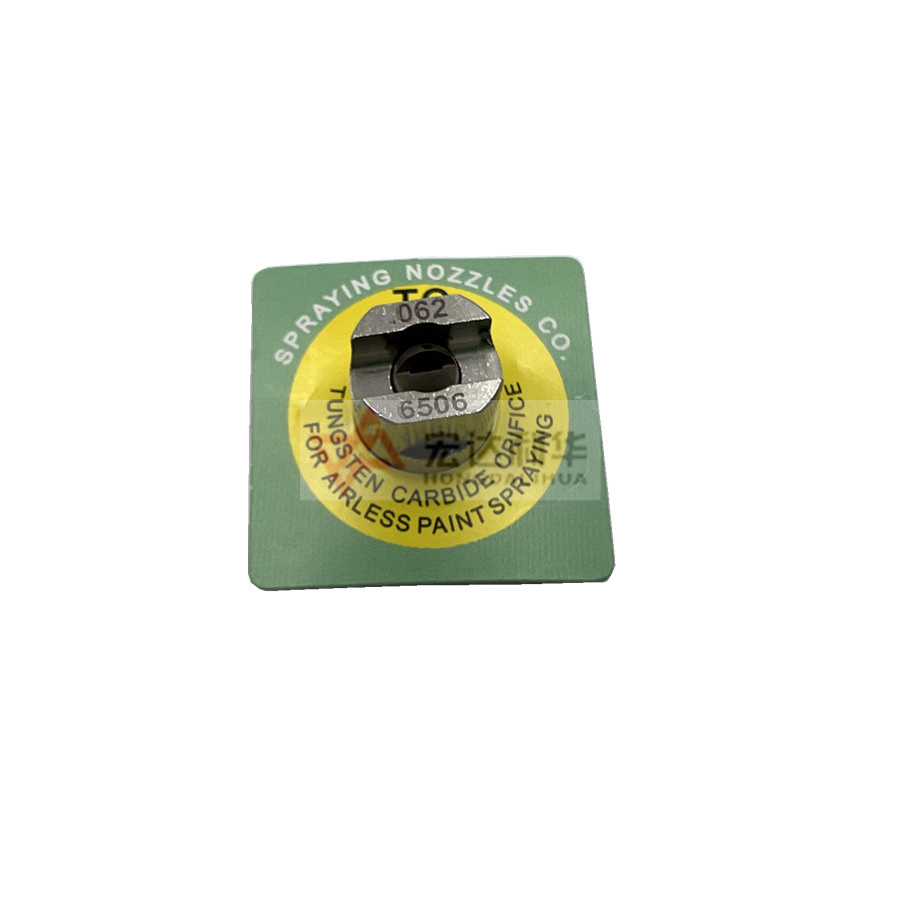

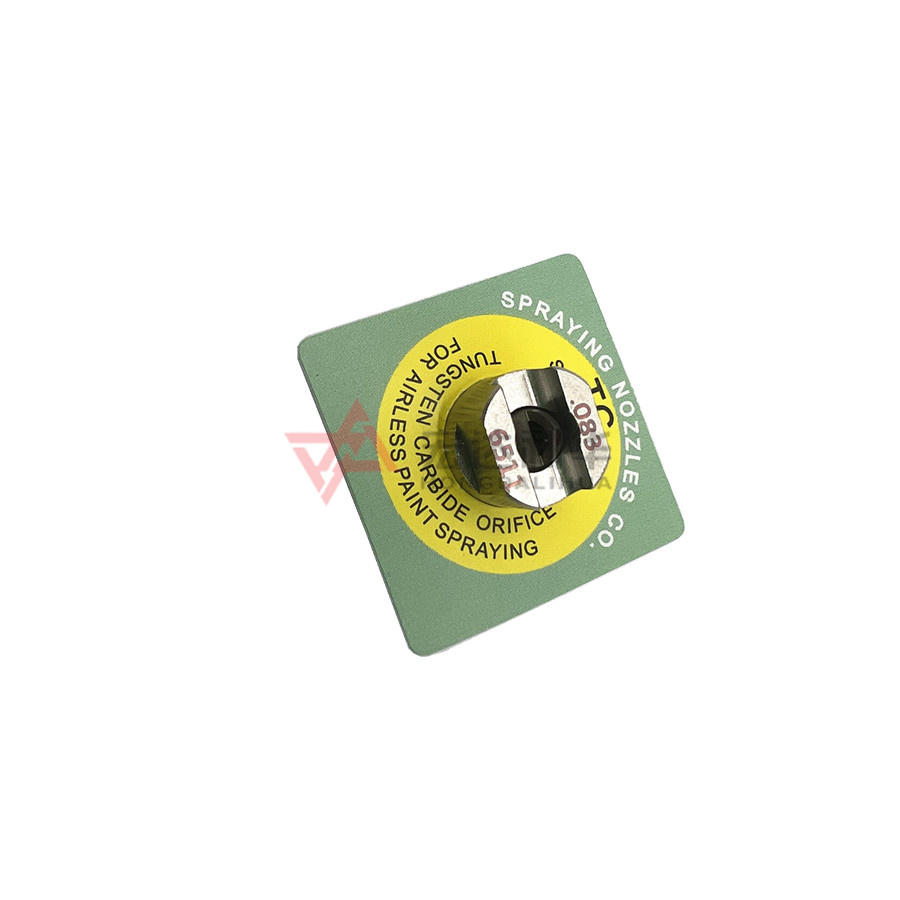

- Tungsten Carbide TC Spray Nozzles

- >

- Tungsten Carbide TC Spraying Nozzles with High Wear Resistance

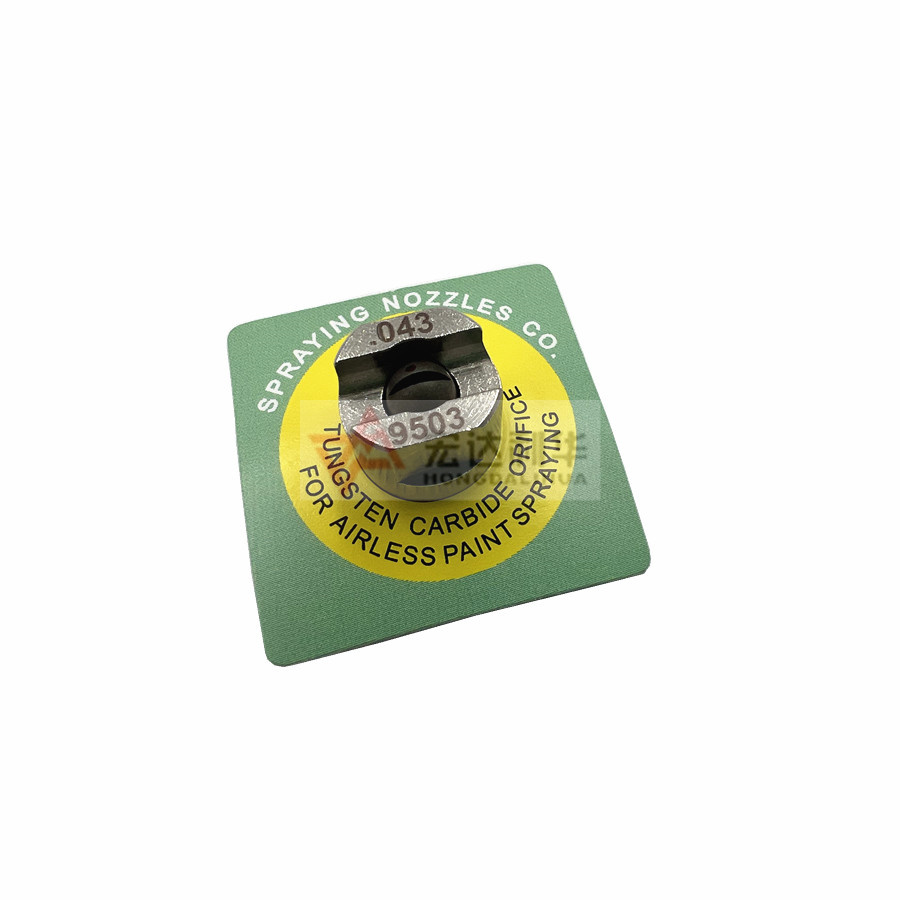

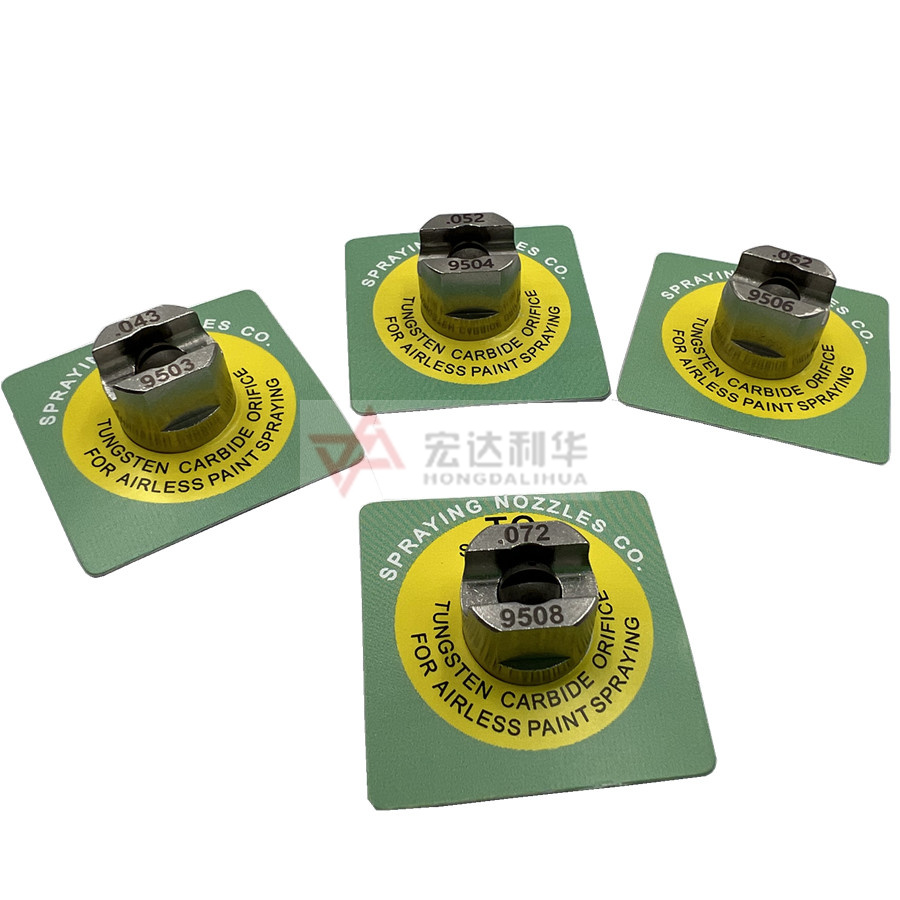

Tungsten Carbide TC Spraying Nozzles with High Wear Resistance

Brand :LIHUA

Product origin :Zhuzhou ,China

Delivery time :7-15 working days

Supply capacity :15 Ton per Month

Tungsten Carbide TC Nozzles price, Discount fuel injector nozzles, cleaning spray nozzles Factory

Advantage

1. Ideal for paint spraying and the application of sealants and protective coatings in automotive manufacturing.

2. Erosion-resistance tungsten carbide orifice insert provides.

3. Excellent Corrosion Resistance.

4. High-impact flat spray pattern with tapered edges, provides even coverage when sprays overlap.

5. Tip orifice inserts is recessed in a solid stainless steel tip body to protect against damage.

Grade Information

| Grade | Density(g/cm3) | T.R.S MPa | Hardness(HRA) | Performance & Application recommended |

| YL10.2 | 14.50 | 3400 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,especially for cut-off tool and sick prick. |

| YG3 | 15.20-15.40 | 1400 | 91.5 | Medium grain,for finishing machining of cast iron and non-ferrous Metals |

| YG6X | 14.90 | 1560 | 91.0 | Qualified for machining of chilled cast iron,alloy cast iron,refractory steel analloy steel.Also qualified for the machining of common cast iron. |

| YS2T | 14.45 | 2800 | 92.5 | Qualified for low speed rough machining,milling,titanium alloy and refractory alloy,especially for cut-off tool and sick prick. |

| YG3X | 15.20-15.40 | 1300 | 92 | Fine Grain,for finishing machining of cast iron and non-ferrous metals |

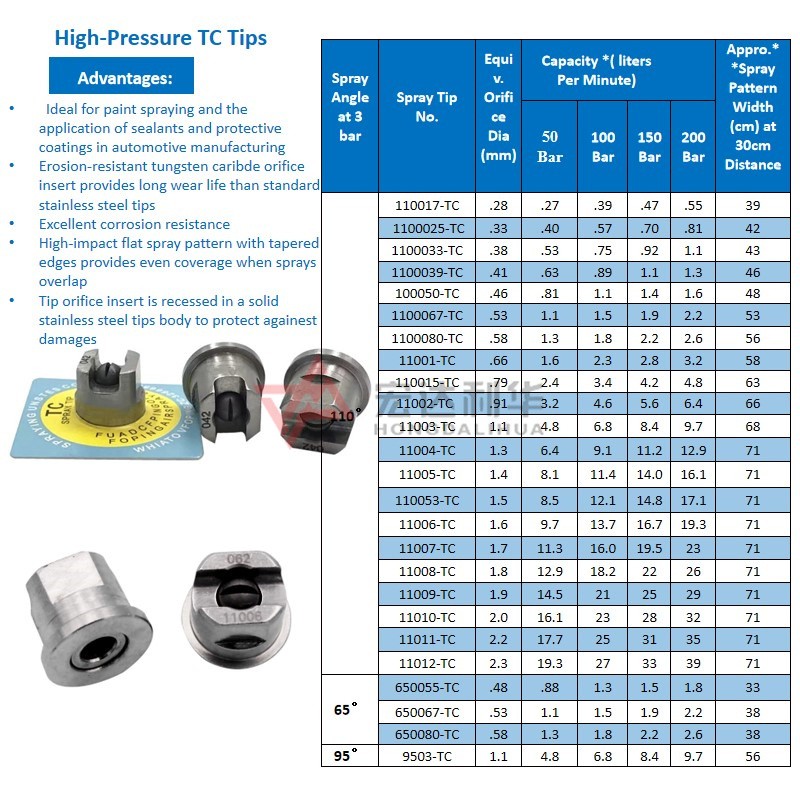

High-Pressure TC Tips Performance Parameter

| Spray Angle at 3 bar | Spray Tip No. |

Equiv.Orifice Dia(mm) | Capacity*(liters Per Minute) | Appro.**Spray Pttern Width(cm)at 30cm Distance | |||

| 50Bar | 100Bar | 150Bar | 200Bar | ||||

| 110° | 110017-TC | 28 | 27 | 39 | 47 | 55 | 39 |

| 1100025-TC | 33 | 40 | 57 | 70 | 81 | 42 | |

| 1100033-TC | 38 | 53 | 75 | 92 | 1.1 | 43 | |

| 1100039-TC | 41 | 63 | 89 | 1.1 | 1.3 | 46 | |

| 100050-TC | 46 | 81 | 1.1 | 1.4 | 1.6 | 48 | |

| 1100067-TC | 53 | 1.1 | 1.5 | 1.9 | 2.2 | 53 | |

| 1100080-TC | 58 | 1.3 | 1.8 | 2.2 | 2.6 | 56 | |

| 11001-TC | 66 | 1.6 | 2.3 | 2.8 | 3.2 | 58 | |

| 110015-TC | 79 | 2.4 | 3.4 | 4.2 | 4.8 | 63 | |

| 11002-TC | 91 | 3.2 | 4.6 | 5.6 | 6.4 | 66 | |

| 11003-TC | 1.1 | 4.8 | 6.8 | 8.4 | 9.7 | 68 | |

| 11004-TC | 1.3 | 6.4 | 9.1 | 11.2 | 12.9 | 71 | |

| 11005-TC | 1.4 | 8.1 | 11.4 | 14.0 | 16.1 | 71 | |

| 110053-TC | 1.5 | 8.5 | 12.1 | 14.8 | 17.1 | 71 | |

| 11006-TC | 1.6 | 9.7 | 13.7 | 16.7 | 19.3 | 71 | |

| 11007-TC | 1.7 | 11.3 | 16.0 | 19.5 | 23 | 71 | |

| 11008-TC | 1.8 | 12.9 | 18.2 | 22 | 26 | 71 | |

| 11009-TC | 1.9 | 14.5 | 21 | 25 | 29 | 71 | |

| 11010-TC | 2.0 | 16.1 | 23 | 28 | 32 | 71 | |

| 11011-TC | 2.2 | 17.7 | 25 | 31 | 35 | 71 | |

| 11012-TC | 2.3 | 19.3 | 27 | 33 | 39 | 71 | |

| 65° | 650055-TC | 48 | 88 | 1.3 | 1.5 | 1.8 | 33 |

| 650067-TC | 53 | 1.1 | 1.5 | 1.9 | 2.2 | 38 | |

| 650080-TC | 58 | 1.3 | 1.8 | 2.2 | 2.6 | 38 | |

| 95° | 9503-TC | 1.1 | 4.8 | 6.8 | 8.4 | 9.7 | 56 |

Get the latest price? We'll respond as soon as possible(within 12 hours)