- Home >

- Products

-

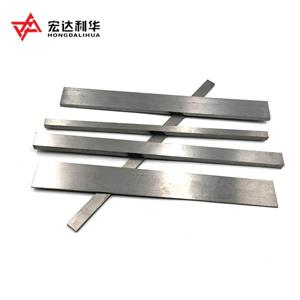

HRC45/55/60/65 Solid Carbide Square/Flats /Radius EndMills For Metal Cutting

Cheap Factory Solid tungsten Carbide Square EndMills For Metal Cutting for sale Suppliers 4. Centered Cutting: Yes 5. Type: Square End Mill / Flat end mill / Metal cutting tool

-

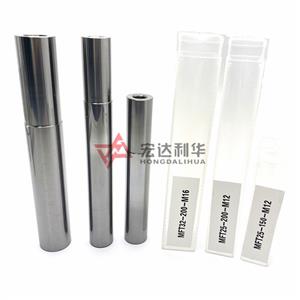

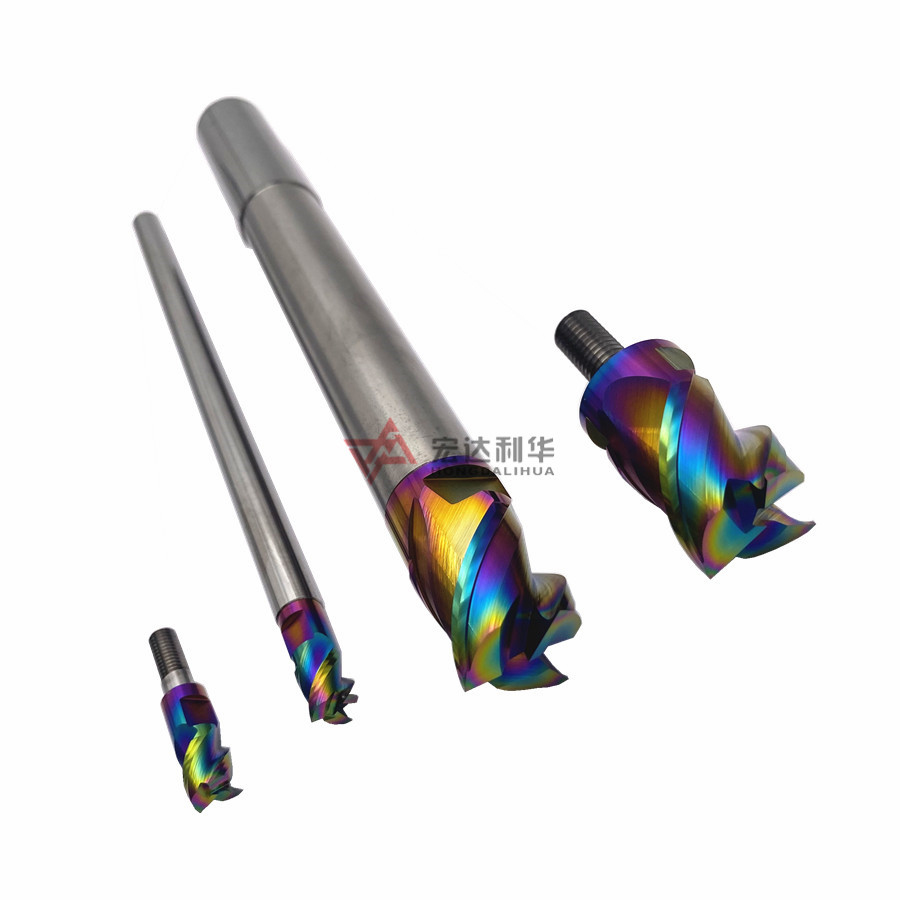

Customize MFT Carbide Screwed Tool Holders with Grinding Thread

High Anti vibration High Pricision +-0.005mm Competitive price - 10~35% discount Fast Shipment -1-7days for both standard size and customized size High quality -100% good feedbacks Fast communication via coco@lihuacarbide.com or hongda@lihuacarbide.com Whatsapp 13973352165 (24 hours avaliable )- Coco SU

-

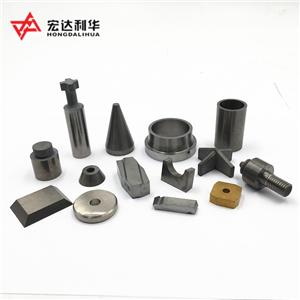

Inch size SA-1 SC-1 SD-2 SE-3 SF-3 L-1 SL-3 SH-1 Carbide Rotary Burr sets For Grinding

Sales Cheap Standard Cemented Carbide Rotary Burr Hand Tool For Grinding Suppliers Carbide Rotary Burrs are used for cutting, shaping, grinding and for the removal of sharp edges, burrs and excess material

-

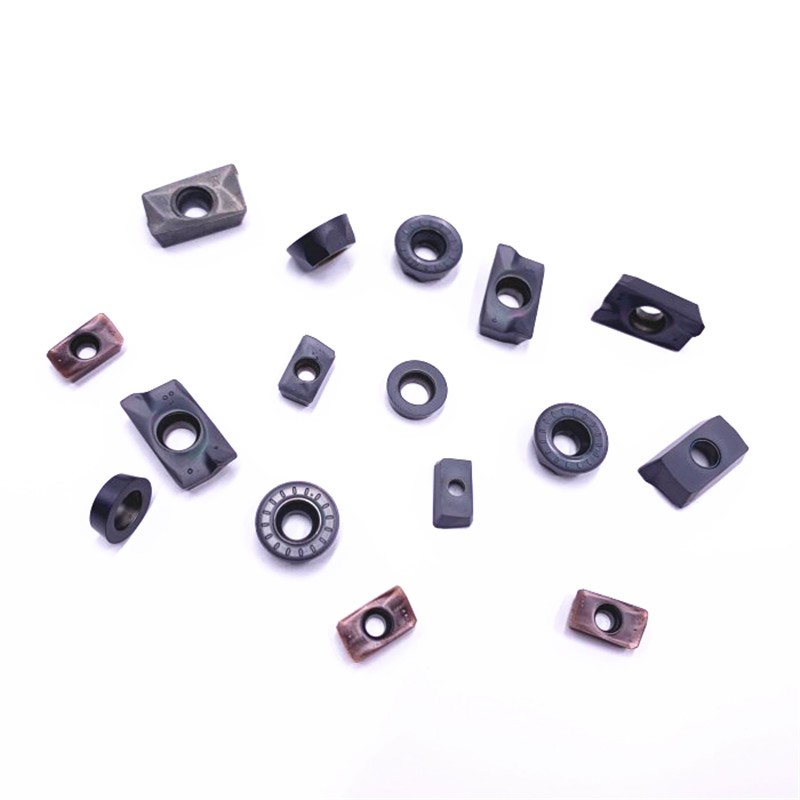

APKT Carbide Milling Insert with Carbide extensions for CNC Machinery Tools

Buy Supply APKT cobalt alloy Carbide Milling Inserts Factory Tungsten Carbide blade is used for cutting wood, metal, or other hard materials. Can be hand-operated or power-driven.

-

OEM Factory 4 Flutes Tungsten Carbide Endmills With AITIN Coated Carbide End Mills

High precision Tungsten Carbide Flat End Mills / Ball nose End Mills / Radius End Mills from original Manufacturer

-

High Hardness PCD Diamond Wire Drawing Dies

Supply china High Hardness PCD Diamond Wire tungsten carbide Drawing Dies manufacturers price construction reinforcement, cables, medical and surgical applications, springs, staples, tire cord,and welding wire.

-

Carbide Various Type Alloy Powder Grits

High quality Discount Carbide Various Type Alloy Powder material Tungsten Grits for Welding Purchasing For example, if a steel cutter can cut 24 hours without grits, it will cut 240 hours after with the tungsten carbide grits.

-

Tungsten Carbide Milling Heads

Advantage: 1.Tungsten carbide head and shank The cutter head and the shank are connected in the same way as the existing products, eliminating the need to purchase a separate shank and saving tool costs. 2.Various cutter heads can be exchanged, high economy value. Composite material design, more environmentally friendly, energy-saving and resource-saving than ordinary tungsten steel knives 3. High accuracy, high rigidity and high efficiency in cutting 4. Reusable grinding after the cutter head is used, saving tooling costs and reducing manufacturing costs